All metal-clad cable conductors shall be stranded, setting the stage for a comprehensive exploration of the benefits, materials, manufacturing processes, applications, safety considerations, and future trends associated with these essential components of electrical infrastructure.

The intricate stranding of conductors in all metal-clad cables unlocks a myriad of advantages, including enhanced flexibility, improved performance under demanding conditions, and extended cable lifespan. This in-depth analysis delves into the various types of stranded conductors employed, the impact of stranding on cable characteristics, and the crucial role of material selection in optimizing cable properties.

1. Stranded Conductors

Stranded conductors offer several advantages in all metal-clad cables. They enhance flexibility, making the cables easier to handle and install, especially in tight spaces or around corners. Stranded conductors also reduce the risk of conductor breakage during installation or under mechanical stress.

Additionally, they provide better current distribution, which improves the overall performance and efficiency of the cable.

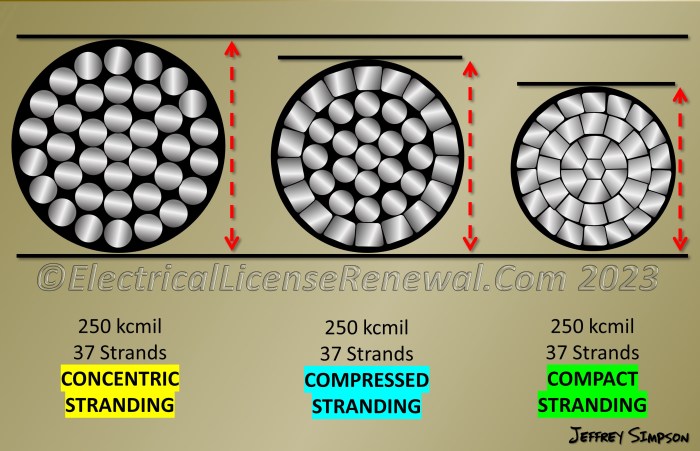

Various types of stranded conductors are used in all metal-clad cables, including:

- Concentric stranded conductors: Consist of multiple layers of stranded wires arranged in a concentric pattern.

- Sector-shaped stranded conductors: Feature individual strands shaped like sectors of a circle, providing improved flexibility and space utilization.

- Rope-lay stranded conductors: Composed of multiple strands twisted together in a helical pattern, offering high strength and flexibility.

The choice of conductor stranding depends on factors such as the cable’s flexibility requirements, current-carrying capacity, and overall performance.

2. Material Considerations

The material used for all metal-clad cable conductors significantly impacts its properties and performance.

- Copper:Highly conductive, ductile, and resistant to corrosion. It is commonly used in all metal-clad cables due to its excellent electrical properties.

- Aluminum:Lightweight, less expensive than copper, and offers good conductivity. However, it is more susceptible to corrosion and has lower strength.

- Alloy conductors:Combine the advantages of different metals to achieve specific properties, such as high strength, corrosion resistance, or improved conductivity.

The material selection for the conductor depends on the specific application requirements, cost considerations, and environmental factors.

3. Manufacturing Processes: All Metal-clad Cable Conductors Shall Be Stranded

The manufacturing processes involved in producing all metal-clad cables with stranded conductors are crucial for ensuring their reliability and performance.

Key steps include:

- Conductor stranding:Strands are drawn, twisted, and bundled together to form the desired conductor configuration.

- Insulation application:Extruded or taped insulation is applied over the stranded conductor to provide electrical isolation.

- Metal cladding:A metal sheath, typically aluminum or lead, is applied over the insulation for mechanical protection and moisture resistance.

- Quality control:Rigorous testing and inspection are conducted throughout the manufacturing process to ensure compliance with industry standards.

Proper stranding techniques and quality control measures are essential to prevent conductor breakage, insulation damage, or other defects that could compromise cable performance.

Frequently Asked Questions

Why are all metal-clad cable conductors required to be stranded?

Stranding enhances flexibility, improves performance under demanding conditions, and extends cable lifespan.

What are the different types of stranded conductors used in all metal-clad cables?

Common types include concentric stranded, rope-lay stranded, and compacted stranded conductors.

How does material selection impact the properties of all metal-clad cables?

Material choice influences conductivity, strength, durability, and other cable characteristics.